INCREASED DEMANDS, FASTER THROUGHPUT – ARE YOU READY?

Armed with innovative and industry-exclusive features, the Hyster® end rider can streamline your picking process and help boost productivity – ultimately increasing throughput.

Precision Pick

Shift Assist

Illumination

Cost of Ownership

DON’T BE UNCOMFORTABLE WHILE GETTING THE JOB DONE.

Proper ergonomic equipment can help you mitigate these issues and maximize the productivity of lift truck operators. The ergonomically designed end rider has your back.

Integrated knee pads

made with durable, contoured rubber delivers industry-leading support to enhance operator comfort; unique waffle pattern provides flexibility and maximizes airflow

Hand rail with auxiliary controls

allows operator access to lift/lower, high speed, and smart shift functions

Operator platform

offers more usable foot space than leading competitors to help promote all-day operator comfort; drain holes align with the platform cushion, pulling moisture down and out of the truck

Platform cushion

exclusive design helps absorb shock and vibration to improve operator comfort and provide steady footing; closed cell construction enhances durability; drain holes improve tractive effort in wet applications; easily removes for cleaning

DURABLE COMPONENTS. SIMPLIFIED SERVICEABILITY.

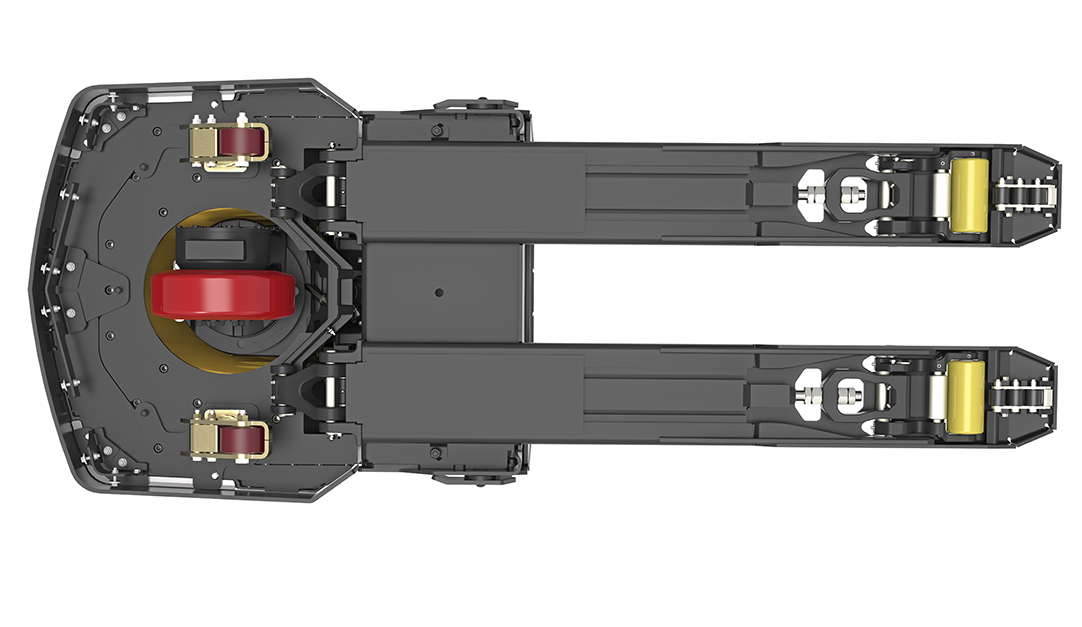

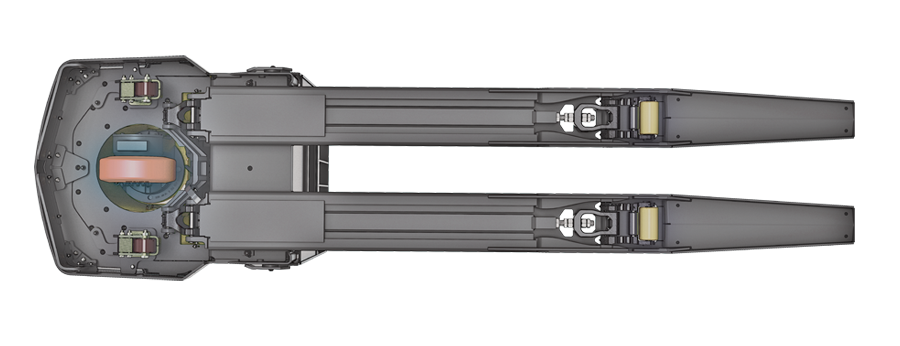

The Hyster End Rider drive tire can be changed in ONE-TENTH OF THE TIME it takes to change the Crown drive tire.*

*Actual drive tire changes by qualified lift truck technician on Hyster B80ZHD2 and Crown PE4500-80. Results may differ depending on specific model and technician.

Heavy-duty frame is one of the toughest in the industry

Stiffest forks both in torsion and deflection

Casters are top mounted for simple access, and can be fully, quickly serviced and adjusted

Electric brakes require no adjustments or maintenance

Extended service intervals (up to 1,000 hours) provide lower cost of operation

All operator padding is closed cell durable rubber for maximum durability

, and “Strong Partners. Tough Trucks.” are trademarks of Hyster-Yale Group, Inc.

, and “Strong Partners. Tough Trucks.” are trademarks of Hyster-Yale Group, Inc.